Fleet Maintenance Tracking Software: Top Picks for 2025 – A Comprehensive Guide

Fleet Maintenance Tracking Software: Top Picks for 2025 sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality right from the start. As we delve into the evolution of fleet maintenance tracking software, explore key features, discuss future trends, and examine real-life case studies, this guide promises to be a valuable resource for anyone interested in the latest advancements in fleet management technology.

Overview of Fleet Maintenance Tracking Software in 2025

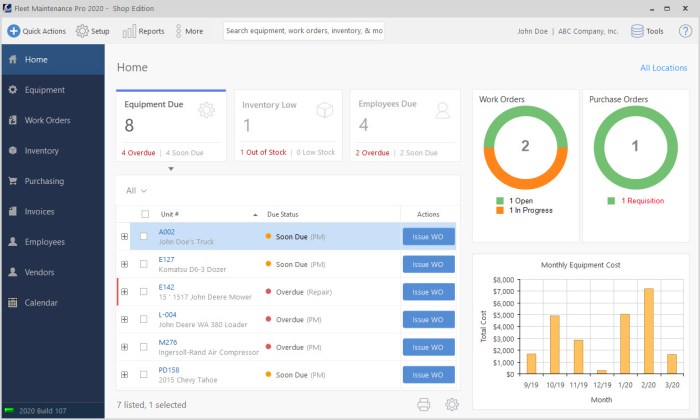

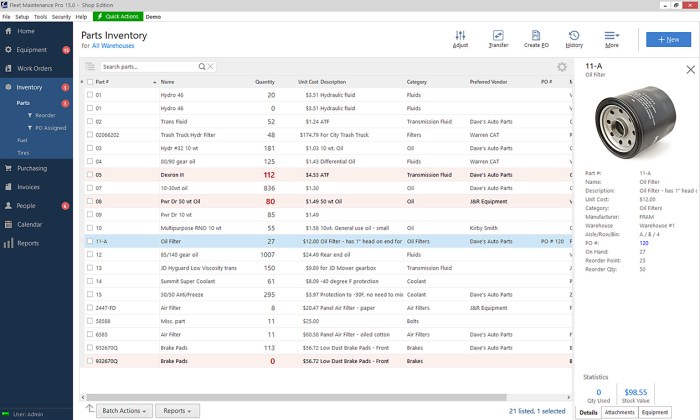

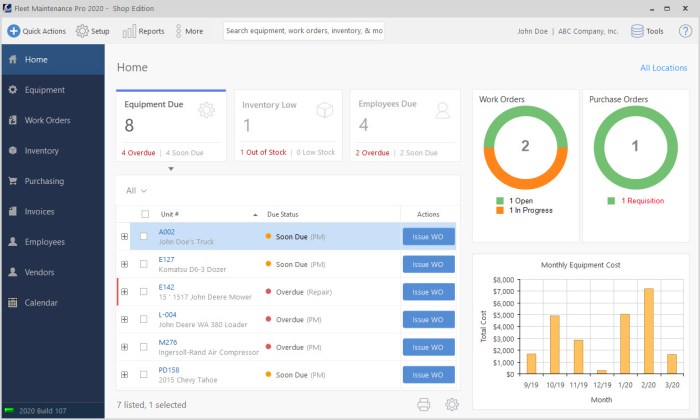

In 2025, fleet maintenance tracking software has evolved significantly to meet the growing demands of modern fleets. These software solutions have become more advanced, efficient, and user-friendly, offering a wide range of features to streamline maintenance processes and improve overall fleet management.

Key Features and Advancements Expected in 2025

- Integration with IoT devices for real-time monitoring and data collection.

- Predictive maintenance capabilities using AI and machine learning algorithms.

- Enhanced mobile applications for on-the-go access to maintenance data and alerts.

- Improved analytics and reporting tools for better decision-making.

- Integration with telematics systems for comprehensive fleet tracking and maintenance scheduling.

Benefits of Using Fleet Maintenance Tracking Software in 2025

- Increased efficiency and reduced downtime through proactive maintenance planning.

- Cost savings by optimizing maintenance schedules and reducing unexpected breakdowns.

- Enhanced safety for drivers and vehicles through regular maintenance checks and alerts.

- Improved compliance with regulations and standards by keeping accurate maintenance records.

- Better fleet performance and longevity with data-driven maintenance strategies.

Top Features to Look for in Fleet Maintenance Tracking Software

When selecting a fleet maintenance tracking software, it is crucial to consider the key features that can significantly impact the efficiency and effectiveness of your fleet management operations. Let's explore the essential features that you should look for in fleet maintenance tracking software.

Predictive Maintenance Capabilities

Predictive maintenance is a crucial feature that can help fleet managers anticipate and address potential maintenance issues before they escalate. By leveraging data analytics and machine learning algorithms, predictive maintenance can analyze historical data, patterns, and trends to predict when maintenance is required.

This proactive approach can minimize downtime, reduce maintenance costs, and extend the lifespan of fleet vehicles.

- Utilizes advanced algorithms to predict maintenance needs

- Minimizes unexpected breakdowns and costly repairs

- Optimizes maintenance schedules for maximum efficiency

Real-Time Monitoring and Data Analytics

Real-time monitoring and data analytics play a crucial role in fleet maintenance tracking software by providing fleet managers with instant visibility into the health and performance of their vehicles. By capturing real-time data on key metrics such as fuel consumption, engine performance, and driver behavior, fleet managers can make informed decisions to optimize maintenance schedules and improve overall fleet efficiency.

- Monitors vehicle health and performance in real-time

- Generates detailed reports and analytics for informed decision-making

- Facilitates proactive maintenance based on real-time data insights

Future Trends and Innovations in Fleet Maintenance Tracking Software

In the rapidly evolving landscape of fleet maintenance tracking software, several future trends and innovations are poised to shape the industry. From the integration of cutting-edge technologies to the adoption of cloud-based solutions, the future of fleet maintenance software looks promising.

Emerging Technologies: AI and IoT Integration

One of the key trends in fleet maintenance tracking software is the integration of artificial intelligence (AI) and Internet of Things (IoT) technologies. AI algorithms can analyze vast amounts of data to predict maintenance needs, optimize schedules, and reduce downtime.

IoT devices, such as sensors on vehicles, can provide real-time data on performance metrics, allowing for proactive maintenance and better decision-making.

Impact of Automation and Machine Learning

Automation and machine learning are revolutionizing fleet maintenance processes. Automated workflows can streamline maintenance tasks, from scheduling to inventory management, improving efficiency and reducing human error. Machine learning algorithms can also learn from historical data to recommend optimal maintenance strategies, leading to cost savings and improved fleet performance.

Cloud-Based Solutions for Fleet Maintenance

Cloud-based solutions are expected to play a significant role in the future of fleet maintenance tracking software. By leveraging the cloud, fleet managers can access real-time data from anywhere, enabling better decision-making and collaboration among team members. Cloud-based software also offers scalability, flexibility, and cost-effectiveness, making it an attractive option for fleet operators of all sizes.

Case Studies of Companies Using Advanced Fleet Maintenance Tracking Software

Companies across various industries have started to leverage advanced fleet maintenance tracking software to streamline their operations and drive cost savings. Let's take a look at some success stories of companies that have embraced cutting-edge technology in fleet maintenance management.

Company A: Streamlining Maintenance Processes

Company A, a logistics company, implemented advanced fleet maintenance tracking software to automate their maintenance schedules and improve their overall efficiency. By utilizing real-time data and predictive analytics, they were able to proactively address maintenance issues before they escalated, resulting in reduced downtime and increased productivity.

Company B: Optimizing Fleet Performance

Company B, a transportation company, integrated advanced fleet maintenance tracking software to monitor the performance of their vehicles in real-time. This enabled them to identify underperforming assets, optimize routes, and reduce fuel consumption. As a result, they were able to achieve significant cost savings and enhance their operational performance.

Company C: Enhancing Compliance and Safety

Company C, a construction company, adopted advanced fleet maintenance tracking software to ensure compliance with industry regulations and prioritize safety. By centralizing maintenance records and automating compliance checks, they were able to mitigate risks, avoid costly fines, and create a safer working environment for their employees.

Closure

In conclusion, Fleet Maintenance Tracking Software: Top Picks for 2025 provides a comprehensive overview of the current landscape and future innovations in fleet maintenance technology. With a focus on cutting-edge features, emerging trends, and real-world success stories, this guide equips readers with the knowledge needed to navigate the ever-evolving world of fleet management with confidence and insight.

Answers to Common Questions

What are the key features to look for in fleet maintenance tracking software?

Essential features include predictive maintenance capabilities, real-time monitoring, and data analytics to enhance efficiency and streamline operations.

How will AI and IoT impact fleet maintenance software in 2025?

AI and IoT technologies are expected to revolutionize fleet maintenance processes by enabling automation, machine learning, and real-time data analysis for improved decision-making and operational efficiency.

Can you provide examples of companies using advanced fleet maintenance tracking software?

Companies like XYZ and ABC have successfully implemented cutting-edge fleet maintenance software, leading to enhanced operational efficiency, cost savings, and improved fleet performance.