Fleet Maintenance Software vs. Manual Tracking: Pros & Cons

Fleet Maintenance Software vs. Manual Tracking: Pros & Cons sets the stage for this engaging discussion, shedding light on the comparison between modern software solutions and traditional manual methods in managing fleet maintenance tasks. As we delve into the advantages and disadvantages of each approach, readers will gain valuable insights into optimizing their fleet maintenance processes.

Overview of Fleet Maintenance Software vs. Manual Tracking

When it comes to managing the maintenance of a fleet of vehicles, companies have the option of using specialized software or manual tracking methods. Fleet maintenance software is a digital solution that helps organizations streamline the process of scheduling, tracking, and managing maintenance tasks for their vehicles.

On the other hand, manual tracking involves using spreadsheets, paper logs, or other non-digital methods to keep track of maintenance activities.

Key Differences

- Fleet Maintenance Software:

- Automates maintenance schedules and reminders.

- Provides real-time visibility into maintenance activities.

- Offers detailed reporting and analytics for better decision-making.

- Manual Tracking:

- Relies on human input and is prone to errors.

- Requires more time and effort to maintain records.

- Limited in scalability and efficiency compared to software solutions.

Importance of Efficient Maintenance Tracking

Efficient maintenance tracking is crucial for fleets to ensure the safety, reliability, and longevity of their vehicles. By keeping accurate records of maintenance activities, companies can minimize downtime, reduce costs, and comply with regulatory requirements. Whether using software or manual methods, having a well-organized maintenance tracking system is essential for optimizing fleet operations.

Pros of Using Fleet Maintenance Software

Fleet maintenance software offers several advantages that can significantly improve the efficiency and effectiveness of managing maintenance tasks for a fleet of vehicles.

Streamlined Maintenance Schedules

- Automated scheduling features help in planning and tracking routine maintenance tasks, such as oil changes, tire rotations, and inspections.

- Notifications and alerts can be set up to remind staff of upcoming maintenance needs, reducing the risk of oversight and ensuring timely servicing.

- Preventive maintenance can be scheduled based on vehicle usage data, optimizing maintenance schedules and prolonging the lifespan of vehicles.

Reduced Downtime

- By proactively managing maintenance tasks, fleet maintenance software can help minimize unexpected breakdowns and downtime, keeping vehicles operational and reducing costly repairs.

- Real-time monitoring of maintenance activities allows for quick identification and resolution of issues, preventing prolonged downtime.

- Improved maintenance planning and tracking enable better utilization of resources, ensuring that vehicles are available when needed.

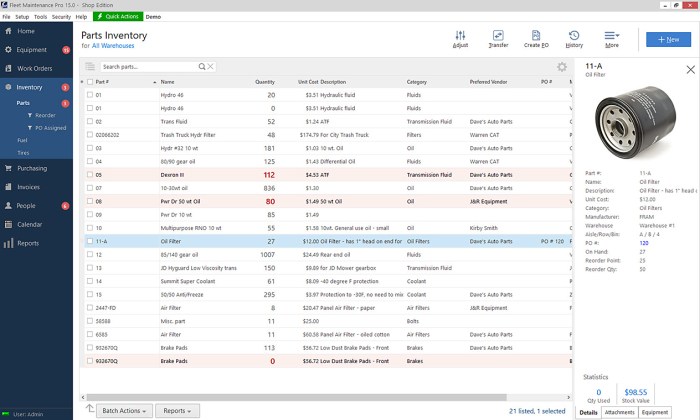

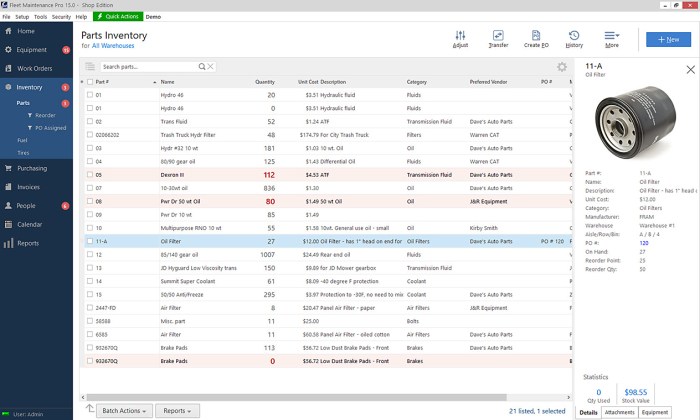

Inventory Management and Parts Tracking

- Software can help maintain detailed records of inventory levels for spare parts and supplies, ensuring that the right parts are always available when needed for repairs.

- Automated reordering functionalities can prevent stockouts and delays in obtaining necessary parts, minimizing disruptions to maintenance workflows.

- Tracking parts usage and performance data can aid in identifying trends, optimizing inventory levels, and reducing costs associated with excess inventory.

Cons of Using Fleet Maintenance Software

When it comes to utilizing fleet maintenance software, there are certain drawbacks and challenges that organizations may encounter. While the software offers numerous benefits, it is essential to consider the potential limitations to make an informed decision.

Lack of Customization

One of the cons of using fleet maintenance software is the limited ability to customize the system to fit specific organizational needs. Off-the-shelf software may not always align perfectly with the unique requirements of a fleet management operation, leading to inefficiencies and potential gaps in data tracking.

Dependency on Technology

Relying solely on fleet maintenance software can pose a risk in terms of dependency on technology. Any technical issues, such as system crashes, bugs, or connectivity problems, can disrupt the maintenance tracking process and impact overall fleet operations. This can result in downtime and delays in servicing vehicles

Training and Implementation Costs

Implementing fleet maintenance software requires training for staff members to effectively use the system. This training can incur additional costs and time commitments for the organization. Moreover, the initial setup and customization of the software may also involve expenses, especially if integration with existing systems is needed.

Data Security Concerns

With the digital nature of fleet maintenance software, data security becomes a critical concern. Storing sensitive information related to vehicle maintenance and operations on a software platform raises the risk of data breaches or cyber attacks. Organizations need to invest in robust security measures to protect their data and ensure compliance with regulations.

Limited Flexibility

While fleet maintenance software offers automation and streamlining of processes, it may lack the flexibility that manual tracking provides. In certain situations where quick modifications or on-the-spot adjustments are required, software systems may not offer the same level of adaptability as manual methods.

Pros of Manual Tracking for Fleet Maintenance

While fleet maintenance software offers numerous advantages, there are still some benefits to sticking with traditional manual tracking methods.

Flexibility in Record-Keeping

Manual tracking allows fleet managers to customize their record-keeping process according to their specific needs. They can easily adjust formats, layouts, and data fields without being constrained by preset software templates.

Cost-Effective Solution

For smaller fleets or businesses with limited budgets, manual tracking can be a more cost-effective solution compared to investing in fleet maintenance software. It eliminates the need for expensive software subscriptions or licenses.

Personalized Attention to Detail

Manual tracking enables fleet managers to pay closer attention to detail when recording maintenance activities. This hands-on approach can result in more accurate and thorough data entry, ensuring nothing is overlooked or omitted.

Cons of Manual Tracking for Fleet Maintenance

Manual tracking systems for fleet maintenance come with several disadvantages that can hinder the efficiency and accuracy of the process. These pitfalls can lead to various issues such as delays in maintenance, increased operating costs, and safety risks for the vehicles and drivers.

Risk of Human Error

- Manual data entry is prone to human error, leading to inaccuracies in maintenance records. This can result in missed maintenance schedules, incomplete documentation, and incorrect information about vehicle repairs.

- Incorrect data input can lead to improper maintenance procedures being carried out, which may compromise the safety and performance of the fleet vehicles.

Data Inconsistencies

- Manual tracking systems often involve multiple individuals handling maintenance records, which can lead to inconsistencies in data entry formats, terminology, and organization. This inconsistency can make it challenging to retrieve and analyze information effectively.

- Without standardized procedures and centralized data management, manual tracking systems can result in data silos and fragmented information, making it difficult to have a comprehensive view of the fleet maintenance history.

Limited Accessibility and Visibility

- Manual tracking systems rely on physical paperwork or spreadsheets, which can be easily misplaced, damaged, or lost. This lack of accessibility can cause delays in accessing critical maintenance information when needed.

- Moreover, manual records may not provide real-time updates on maintenance activities, making it challenging for fleet managers to have a timely overview of the maintenance status of each vehicle.

Ultimate Conclusion

In conclusion, Fleet Maintenance Software vs. Manual Tracking: Pros & Cons highlights the importance of choosing the right maintenance tracking method for your fleet. By weighing the pros and cons of both software and manual tracking, fleet managers can make informed decisions to enhance the efficiency and effectiveness of their maintenance operations.

Questions Often Asked

What are the risks of relying solely on fleet maintenance software?

Overdependence on software may lead to issues such as system failures, data loss, or lack of human oversight that can impact maintenance operations. It's important to have backup plans and manual checks in place.

When is manual tracking preferred over fleet maintenance software?

Manual tracking may be preferred in situations where there is limited access to technology, simplicity is key, or when a more hands-on approach to maintenance tracking is desired.